By W. Jon Wallace, CSP, MBA

Do your electrical workers (qualified persons) perform electrical work on energized electrical conductors? If so, appropriate electrical protective clothing is needed to protect your employees from the risks associated with an electrical arc flash.

More than 600 people die annually in the United States from electrocution and 30,000 suffer non-fatal electrical accidents. Approximately 75% of electrical injuries are caused from an electrical arc flash and subsequent fireball igniting the electricians clothing.

The following article contains valuable information on performing an electrical flash hazard analysis to determine the necessary electrical Personal Protective Equipment (PPE).

The Hazards of Electric Arc Flashes

Arc flashes cause electrical equipment to explode, resulting in an arc-plasma fireball. Temperatures may exceed 35,000° F (the surface of the sun is 9000° F). These high temperatures cause rapid heating of surrounding air and extreme pressures, resulting in an arc blast. The arc blast will likely vaporize all solid copper conductors; solid copper expands to 67,000 times its original volume when it is vaporized. In addition, measurements taken on a test mannequin during a laboratory arc flash detected sound levels of 141.5 decibels at two (2) feet from the blast, and pressure levels of 2,160 pounds per Square foot (psf) in the immediate vicinity of the blast.

An electric arc flash can ignite an employee’s flammable clothing causing severe burns; the intense light of an arc flash can cause cataracts; the tremendous sound pressure may damage an employee’s hearing; and the pressure levels could knock an employee down. Also, flying shrapnel could result in serious injury, or death.

Prevention of Arc Flash Incidents

By far, the best way to prevent an electric arc flash is to always deenergize and lockout/tagout all electrical equipment prior to performing servicing and maintenance activities. OSHA 29 CFR 1910.333 (a)(1) states: “Live parts to which an employee may be exposed shall be deenergized before the employee works on or near them, unless the employer can demonstrate that deenergizing introduces additional or increased hazards or is infeasible due to equipment design or operational limitations. Live parts that operate at less than 50 volts to ground need not be deenergized if there will be no increased exposure to electrical burns or explosion due to electric arcs.”

Some examples of increased or additional hazards may include: interruption of life support equipment, deactivation of emergency alarm systems, atmospheric monitoring equipment, or shutdown of hazardous ventilation equipment. Examples where it may be infeasible to deenergize equipment include performing diagnostics and testing (e.g., start-up or troubleshooting) that can only be performed with the circuit energized.

Electrical Safety-Related Work Practices

If electrical equipment must remain energized while servicing and maintenance is performed, electrical safety-related work practices must be utilized by qualified employees as outlined by OSHA in 29 CFR 1910.331 – 1910.335. In addition to OSHA’s requirements, NFPA 70E Standard for Electrical Safety in the Workplace 2024 Edition contains requirements for performing a flash hazard analysis.

Flash Hazard Analysis and Flash Protection Boundary

Prior to commencing work on electrically energized conductors > 50 volts, NFPA 70E Article 130.4 (A) requires that a flash hazard analysis be performed to identify work tasks that must be performed while electrical equipment remains energized. Instead of performing a detailed analysis, however, Table 130.7 (C)(15)(a) for alternating current (ac) and Table 130.7 (C)(15)(b) for direct current (dc) may be utilized to identify various job tasks and the corresponding hazard risk category.

NFPA 70E Article 130.5 (E) requires employers to establish a flash protection boundary – a distance from exposed energized electrical parts at which an employee could sustain a second degree burn if an electric arc flash were to occur. Employees performing work on energized conductors inside this boundary must be protected with appropriate Personal Protective Equipment (PPE).

Please note: you must satisfy the conditions to utilize the NFPA 70E tables listed above. Most facilities opt for a detailed arc flash study performed by a qualified professional engineer (e.g., electrical engineer).

Selection of Personal Protective Equipment

Once the hazard risk category has been determined, Table 130.7 (C)(15)(c) [Personal Protective Equipment (PPE)] is consulted to determine the appropriate PPE. An example is listed below.

Example: Employee is working on an energized panelboard (including voltage testing) rated < 240 volts.

Required PPE: Task is listed as a hazard risk category one (1). In addition to voltage rated gloves, Table 130.7 (C)(15)(c) specifies the following PPE: arc-rated flame retardant clothing (long-sleeve shirt and pants or coveralls), hard hat and safety glasses.

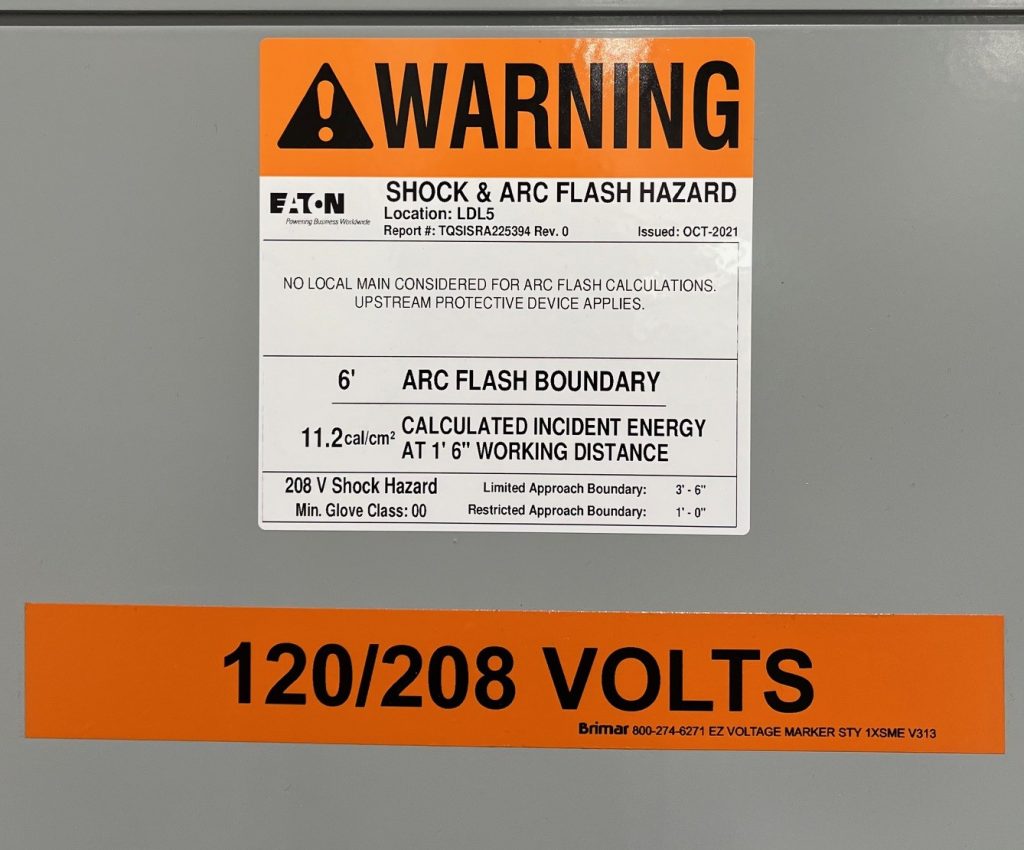

Arc Flash Marking on Field Breakers

In addition to the flash hazard analysis and PPE requirements specified in NFPA 70E, Article 130.5 (H) require equipment labeling: “Electrical equipment such as switchboards, panelboards, industrial control panels, meter socket enclosures and motor control centers in other than dwelling occupancies, that are likely to require examination, adjustment, servicing, or maintenance while energized, shall be marked with a label containing all the following information:

(1) Nominal system voltage

(2) Arc flash boundary

(3) At least one of the following:

a. Available incident energy and the corresponding working distance, or the arc flash PPE category in Table 130.7 (C)(15)(a) or Table 130.7 (C)(15)(b) for the equipment, but not both

b. Minimum arc rating of clothing

c. Site-specific levels of PPE

An example of an arc flash label is shown below.

(image from author’s collection)

Summary

Arc flash hazards pose a serious risk to employee safety; proper safe work practices must be utilized. Electrical equipment > 50 volts must be deenergized and lockout/tagout followed prior to servicing and maintenance unless doing so would increase hazards or is infeasible. Remember, convenience is not an acceptable reason for keeping equipment energized during servicing and maintenance. If electrical equipment must remain energized during servicing and maintenance, NFPA 70E should be consulted to determine flash hazard boundaries as well as required PPE. Finally, circuit breakers and electrical disconnects must be marked to warn qualified employees of potential arc flash hazards.

If you have any questions concerning this article or other safety issues, please contact W. Jon Wallace, “The Safety Guru”, at 919.933.5548 or by e-mail